Technical features of the system

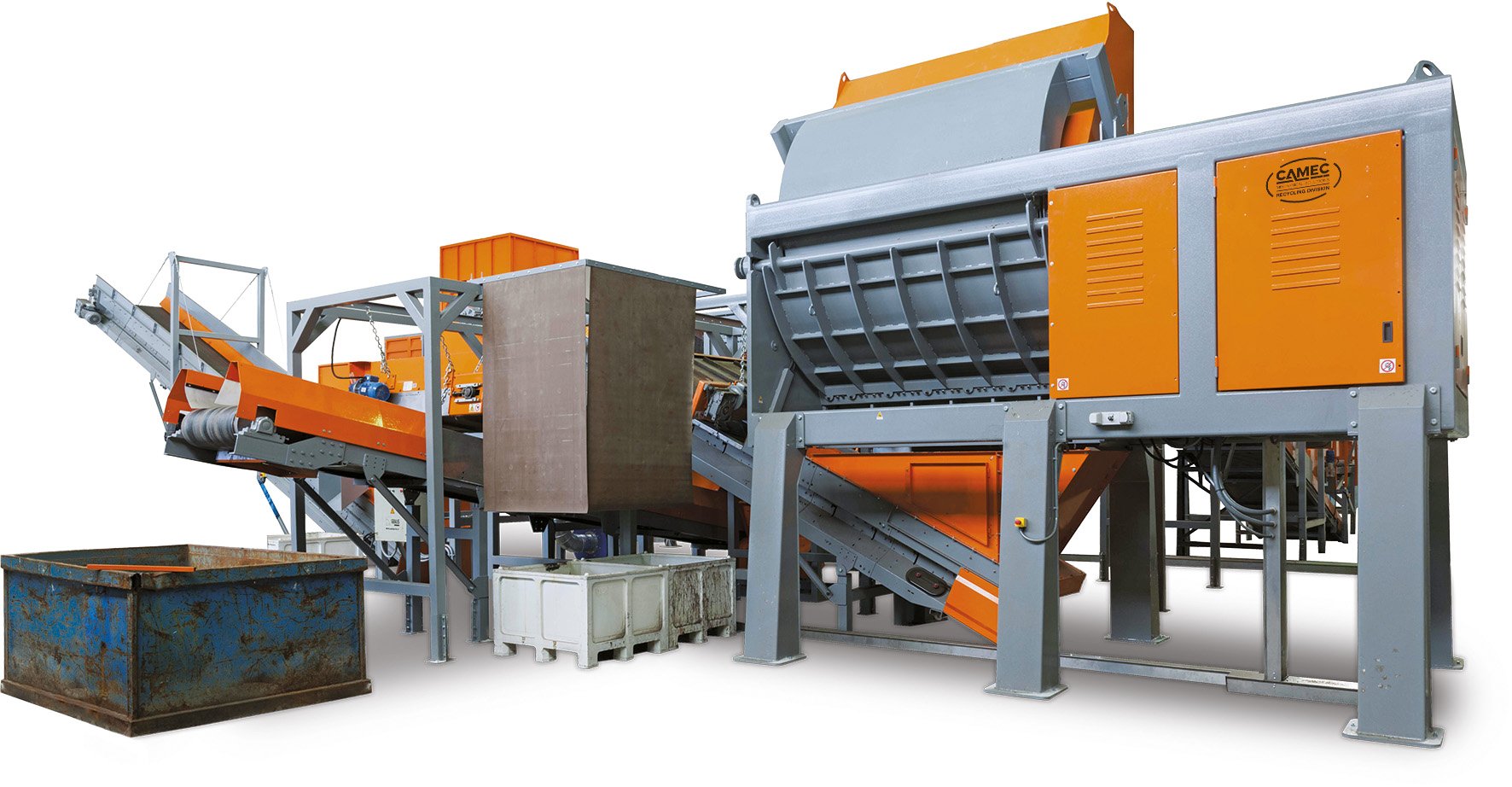

The material is loaded on the conveyor belt that feeds the primary shredder GL620 or directly into the shredder according to the space available. Thanks to a shock detection system, which these shredders are equipped with, the presence of non-shredding material cannot cause damages and therefore longer machine stops. The shredder reduces the material in homogenous and consistent pieces that are de-ironized through a ferrous metals separator and from which the non-shredding bodies are removed through the Air Separator. After this, the material is processed by the shredder GS650 that reduces the material at the required pieces (30/50/80 mm…). The system CDR/CSS is equipped with an aspiration system for the dust that is created during the process of shredding and separation. Separators for non-ferrous metals, disk screen and customized transport systems are some of the options that can be integrated in the system according to the characteristics of the input material and the needs of the customer.

German

German English

English